Spi A 3 Finish

SPI Finish A3 — Grade #15, 10 Grit Diamond Buff By admin T October 6th, 16 SPI Mold Finish Standard Comments Off on SPIA Class mold finish standard Share This Story, Choose Your Platform!.

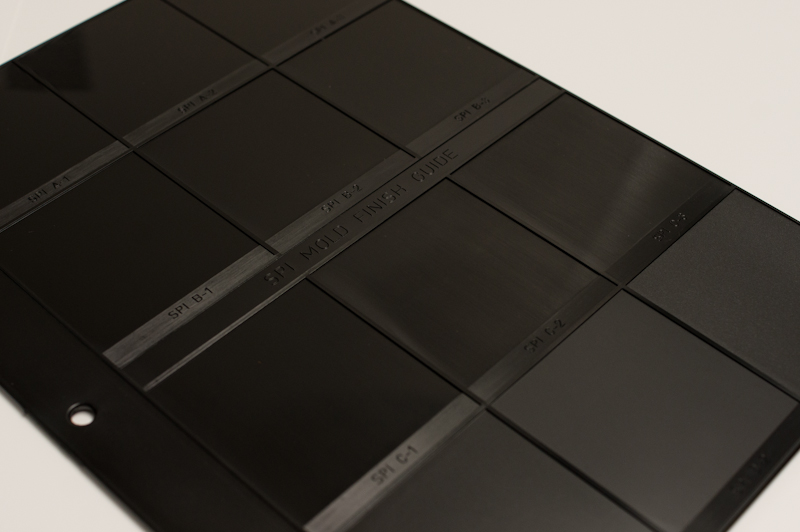

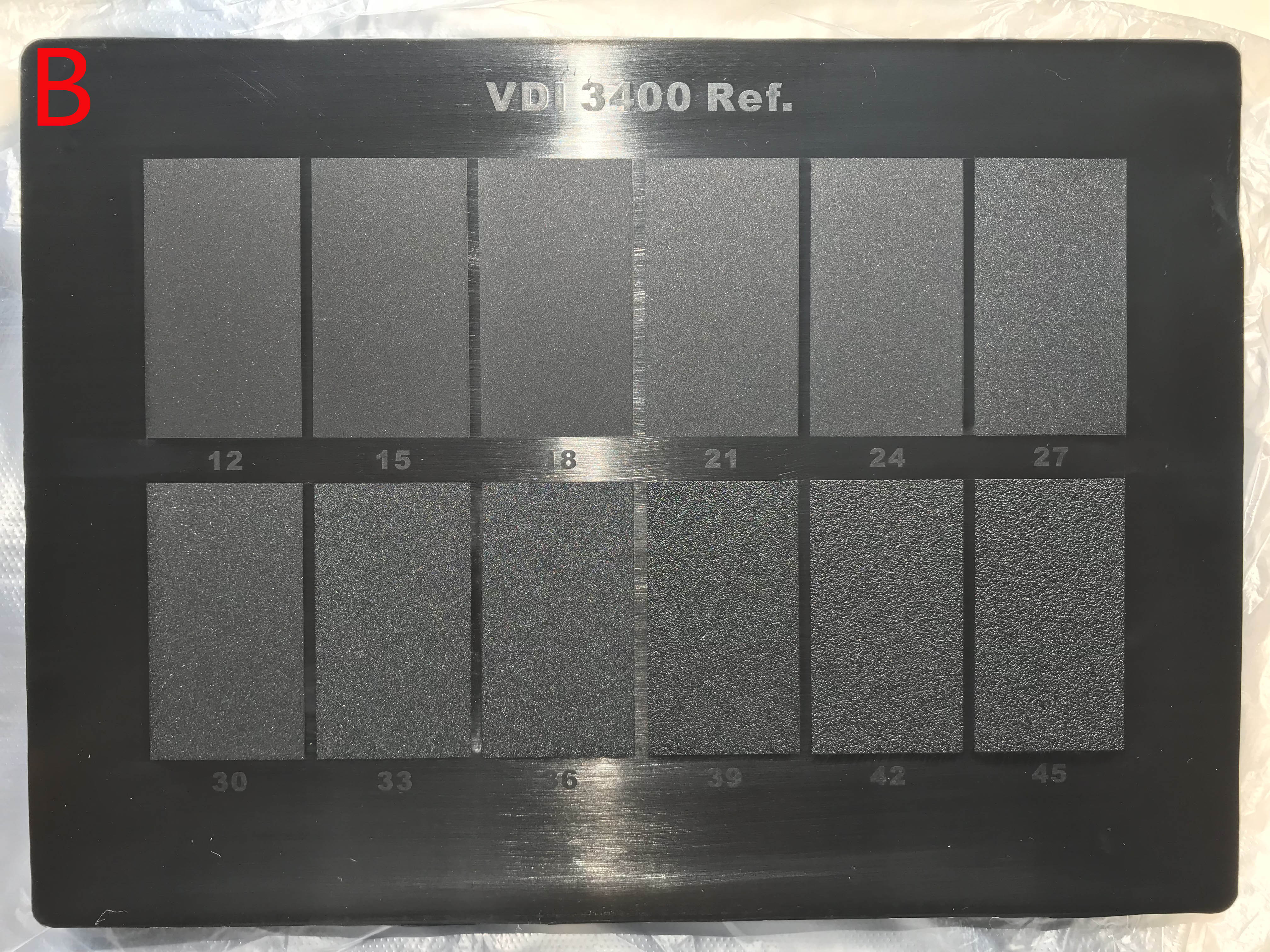

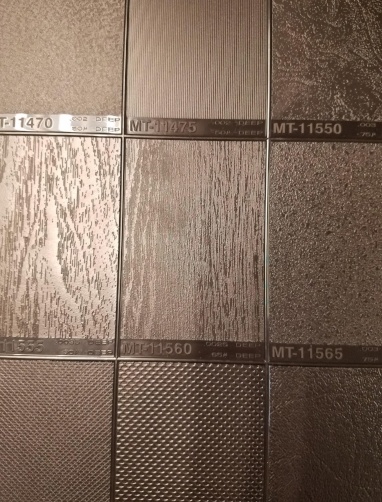

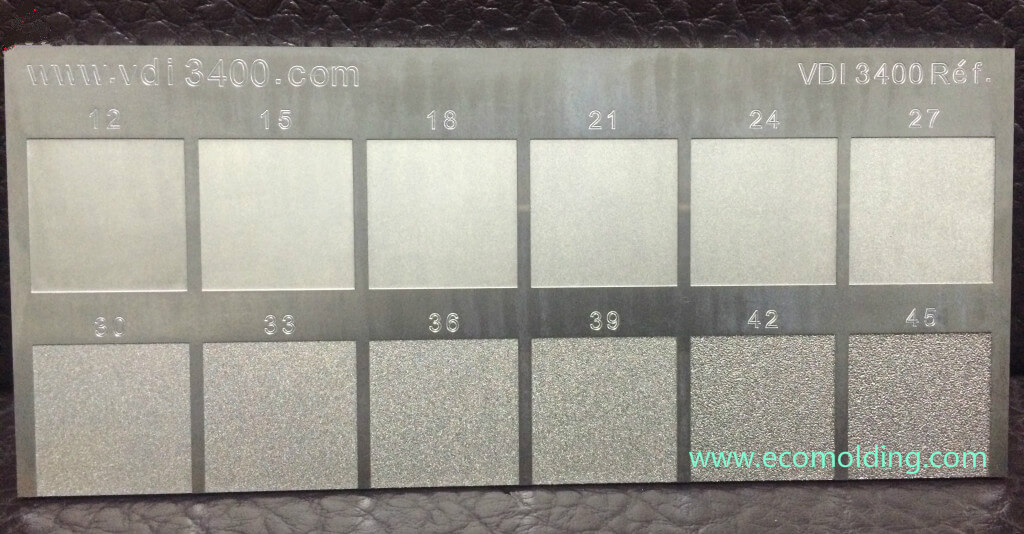

Spi a 3 finish. To ensure color consistency, SPI uses precise bin selection and strict quality processes to maintain a 3step (MacAdam) SDCM on all white LED lampings Published LED luminaire wattages are calculated using a typical power supply efficiency of %;. F steel plate size 25×48mm of SPI finish standard with 12 pcs plate SPI Finish surface standard scale of SPIA1/ SPI/ SPIA3/ SPIB1/ SPIB2/ SPI/ SPIC1/ SPIC2/ SPIC3 making by Polish to achieve SPI Finish standard scaleof SPID1/ SPID2/ SPID3 making by Sandblasting to achieve Grain Number VDI 3400 Carbon Fiber Texture Home. And SPIC1, right, a 600 grit stone polish that removes tool marks but is still not a highend.

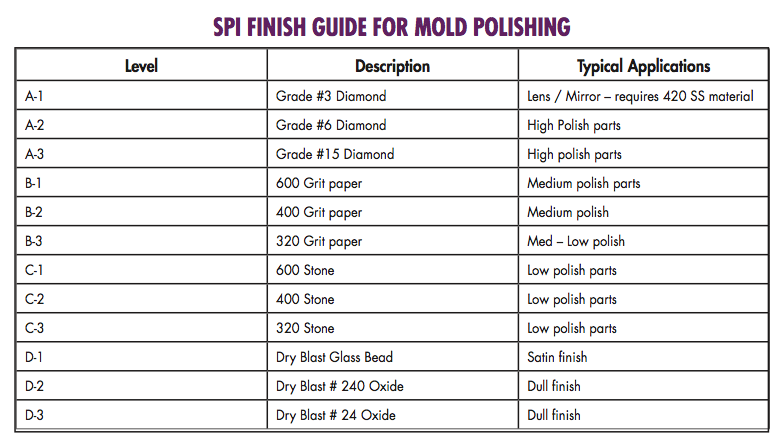

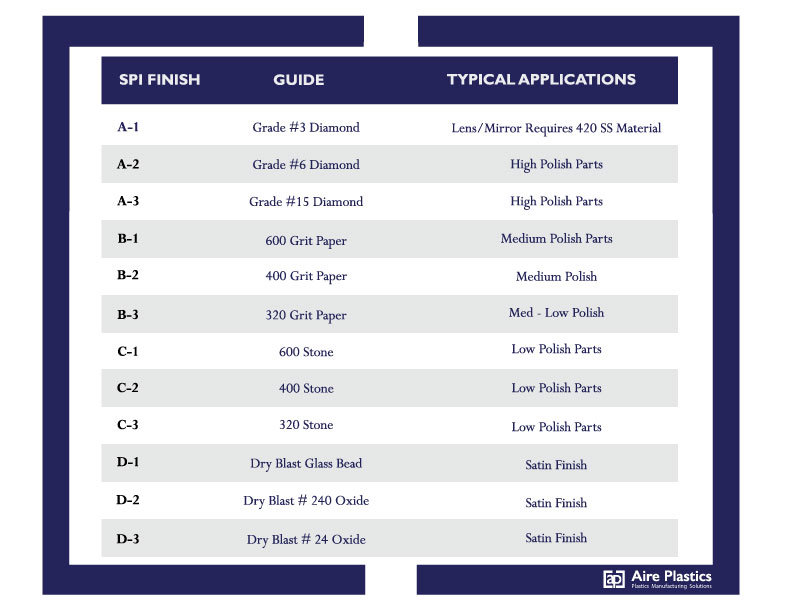

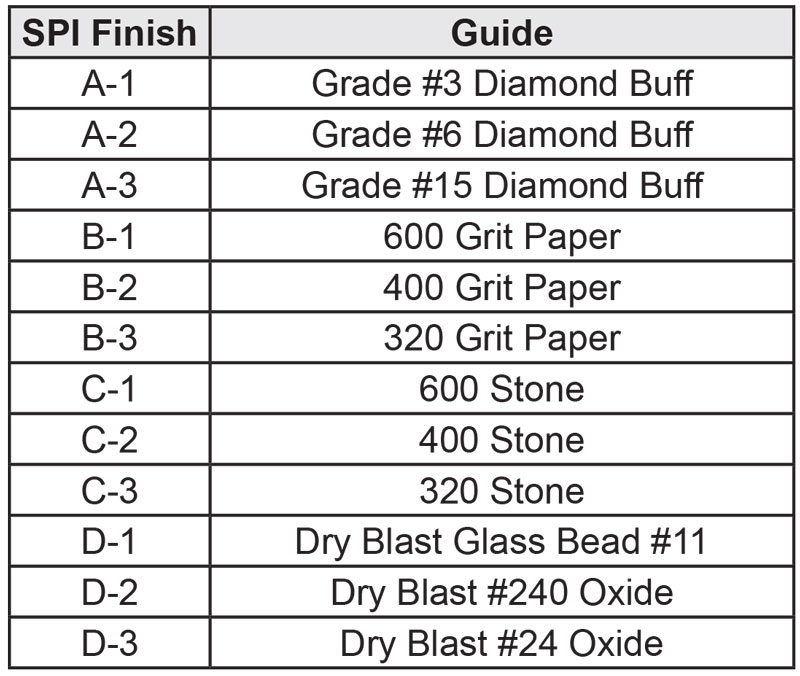

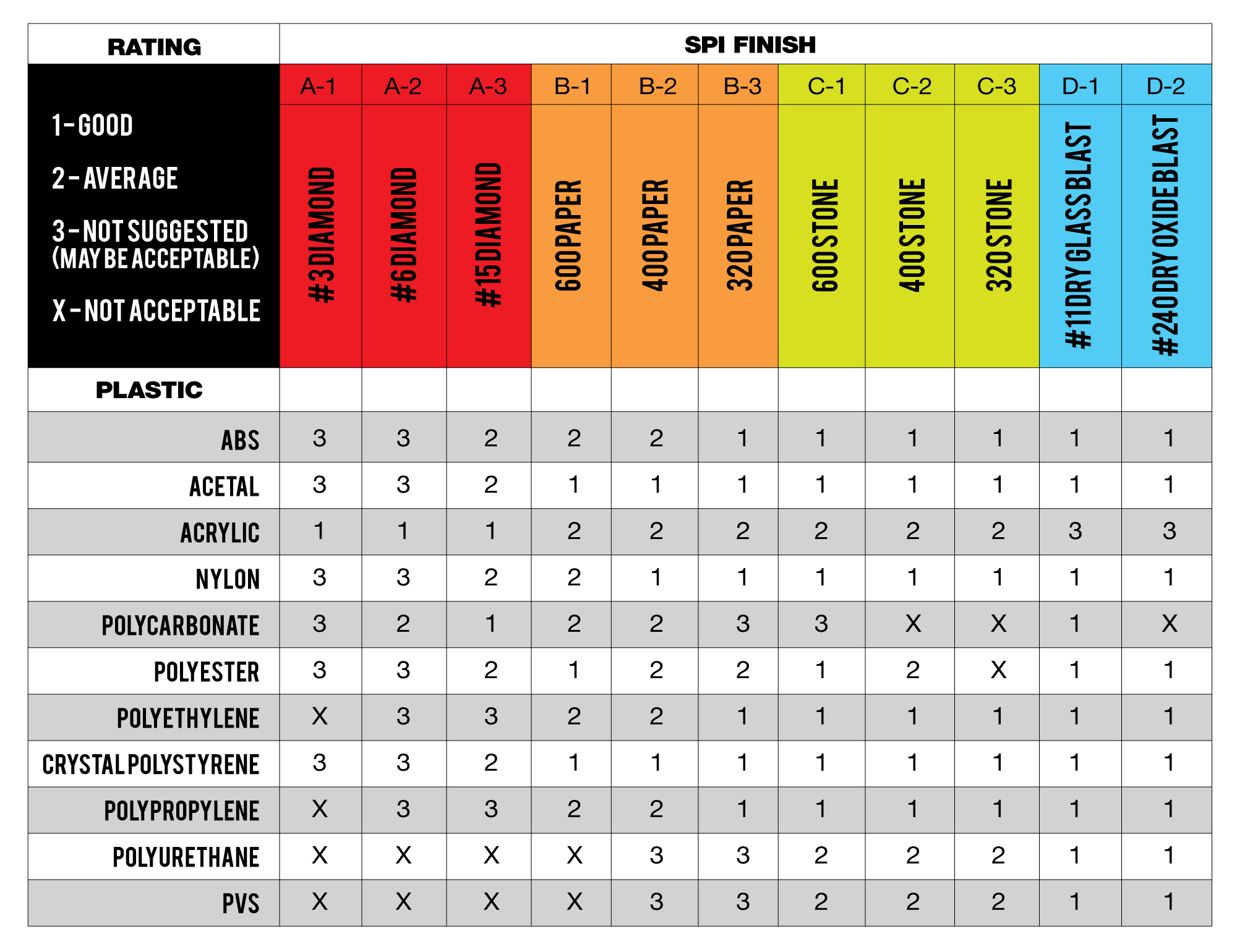

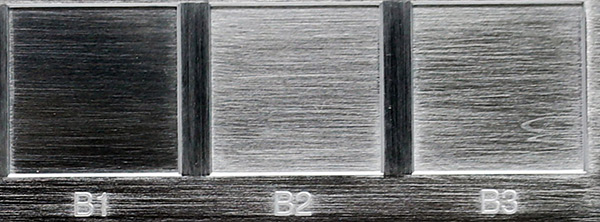

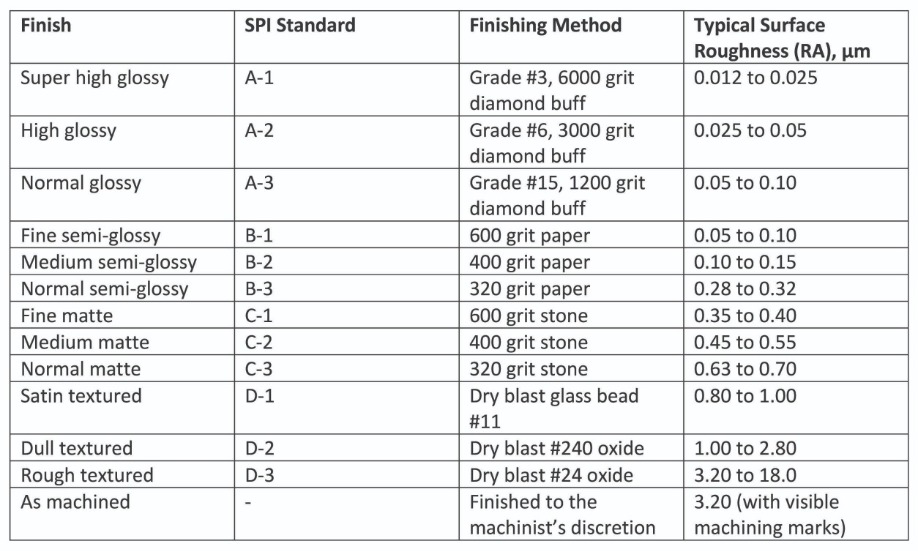

SPI = EV / PV = 14,400 / 18,000 = 08 This means that for every estimated hour of work, the project team is only completing 08 hours (just over 45 minutes) If the ratio has a value higher than 1 this indicates the project is progressing well against the schedule If the SPI is 1, then the project is progressing exactly. Complete Guide to Surface Finish Symbols, Charts, RA, RZ, Measurements, and Callouts Definition of Surface Finish Before we get on with Surface Finish Symbols, let’s understand how Surface Finish is defined Engineering prints call out a great many things in their attempt to make sure the part that gets made matches the designer’s intent. SPI Finish A1 — Grade #3, 6000 Grit Diamond Buff SPI Finish — Grade #6, 3000 Grit Diamond Buff SPI Finish A3 — Grade #15, 10 Grit Diamond Buff NONGLOSSY SURFACE, PAPER POLISH SPI Finish B1 — 600 Grit Paper SPI Finish B2 — 400 Grit Paper SPI Finish — 3 Grit Paper ROUGH SURFACE, STONE POLISH SPI Finish C1 — 600 Grit Stone.

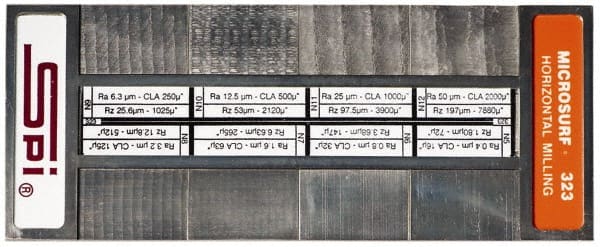

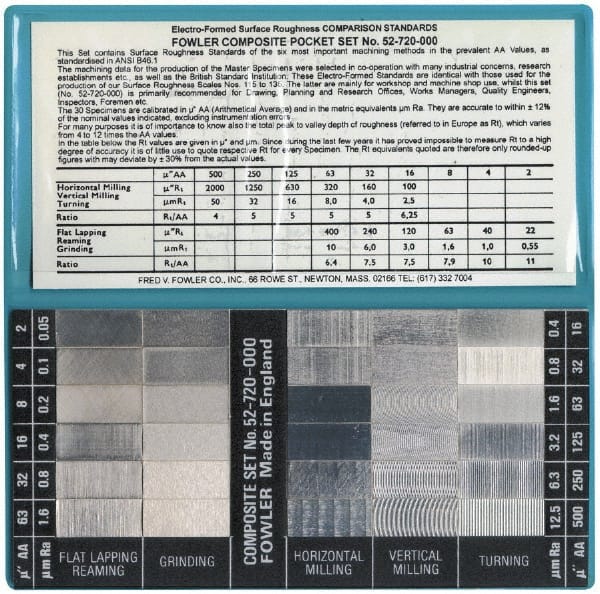

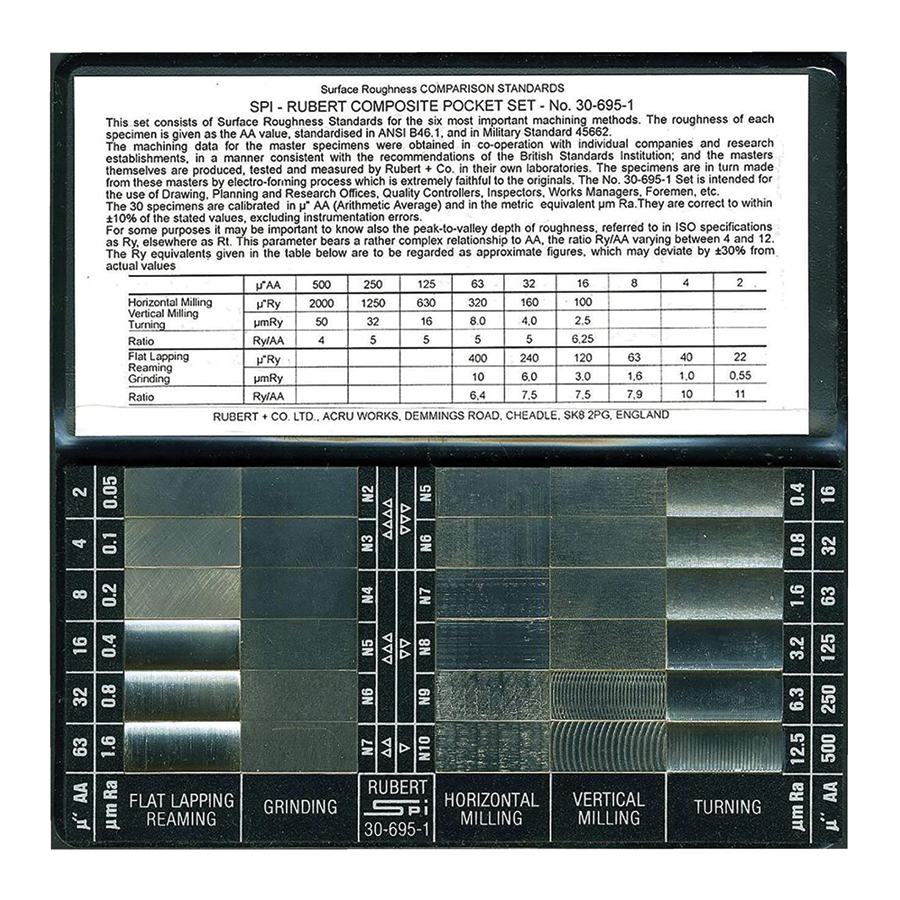

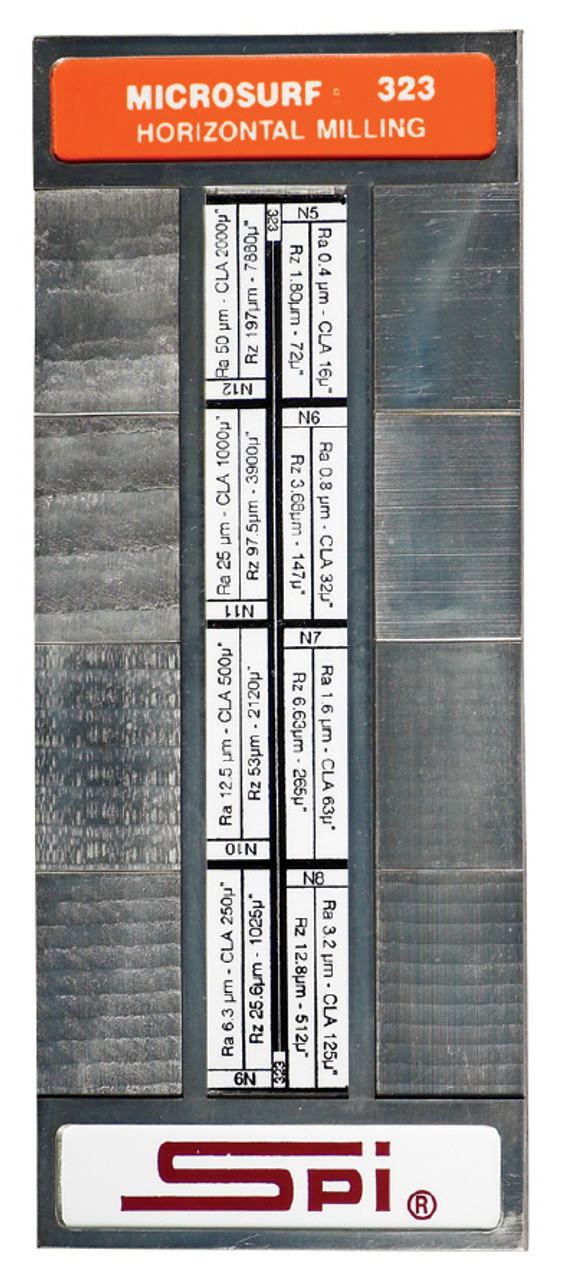

Injection Molding SPI A1 SPI SPI A3 SPI B1 600 Grit Paper Typical Application Medium polish parts SPI B2 400 Grit Paper Typical Application Medium polish parts SPI 3 Grit Paper Typical Application MediumLow polish parts SPI C1 600 Stone Typical Application Low polish parts SPI C2. What is SPI/SPE #3 A discussion started in 03 but continuing through 18 03 Q I received a drawing specifying an SPE/SPI #3 finish on nontextured surfaces and I can't find what this means I looked on the SPI and SPE websites and they have no info available Can you tell me what this polish spec means, and what the #3 means?. Machining surface finish chart, comparator, method, degree, Ra, Rz, RMS As for machining to iron and steel castings, the surface finish smooth degree is also an important requirement The following is the conversion chart is from dandong foundry, for Ra (um), Ra (micro inch), Rz (um), RMS and finish degree in China and USA, including the.

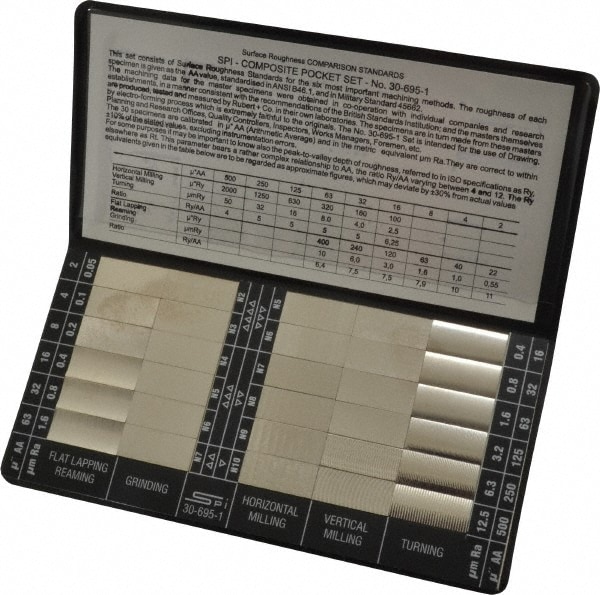

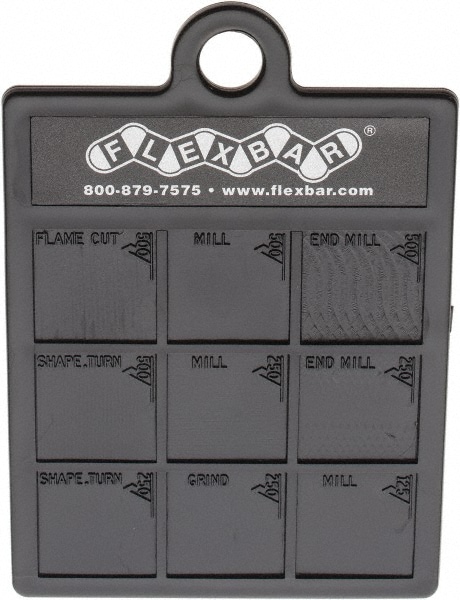

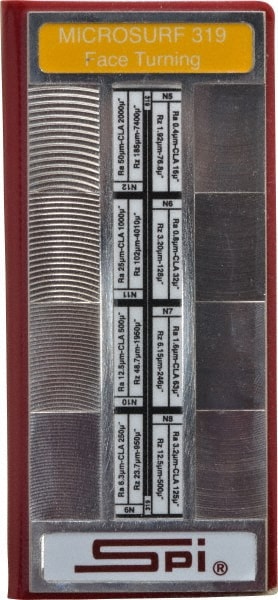

Inside areas polished spid2 or better all outside surfaces to be spia3 finish thread data 400 finish0 pitch (5 tpi) approx 11/8 turns advertising drawing not for quality control weight 400 smooth cap see note pp mp proprietary and confidential the information contained in this drawing is the sole property of comet tool. An SPI A3 is a fine choice for release where a high gloss appearance is not required All diamond finishes work well with chrome and nickel Paper Finishes, SPI B1 to – Next to diamond polishing, paper finishes are the second most refined finishes available. The pocket SPI Mold Finishing Guide has a 72 RC hardfinished surface that will retain exact finisthes for years and includes a direct crossreference between the roughness averaage and SPI scales for ease in comparison We were founded in 1978, by brothers Steve and Mike Bales Back then, we only offered diamond polishing, but we grew quickly.

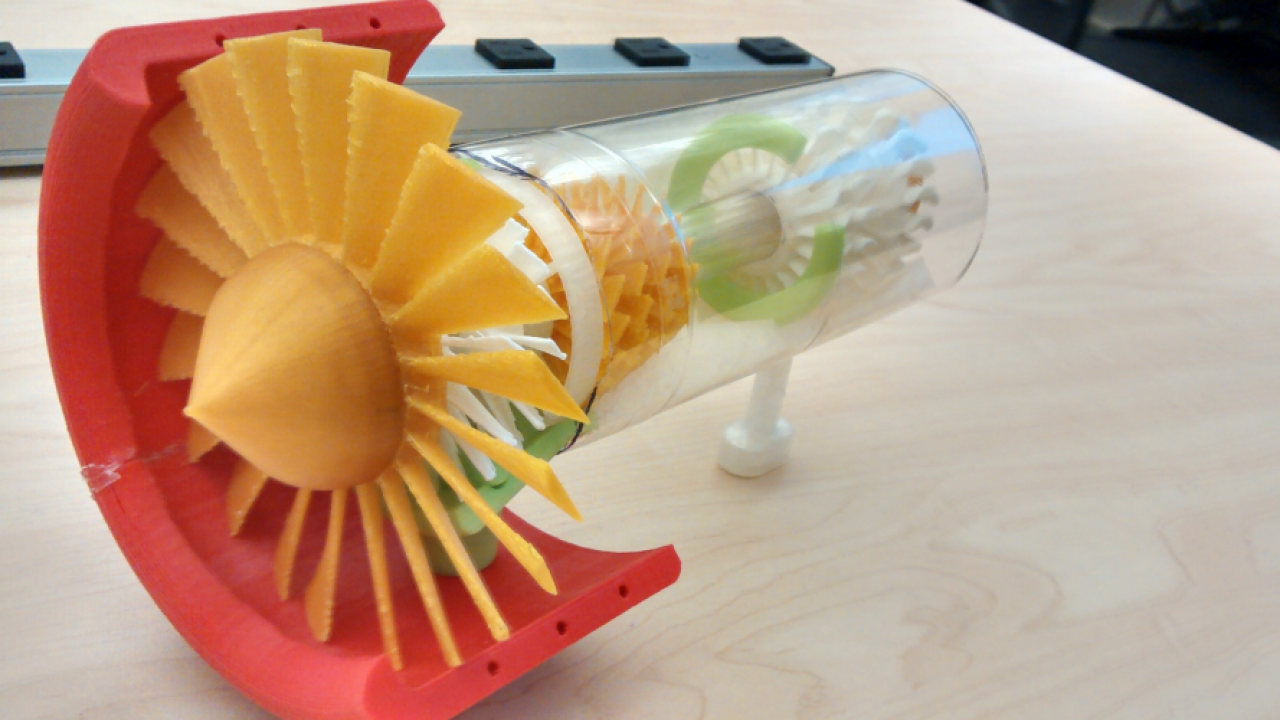

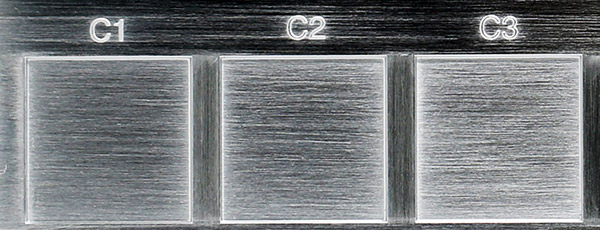

SPI classifies this finish type across grades C1, C2, and C3 The molds used for matte finish are polished using fine stone powders Diecast parts, industrial parts, and consumer goods all use a matte finish This finish not only gives a good aesthetic appearance, but also helps mask machining marks. The SPI* is the most widely used diamond finish, providing good release and good visual parts An SPI A3 is a fine choice for release where a highgloss appearance is not required All diamond finishes work well with chrome and nickel coatings *SPI® is a registered trademark of Plastics Industry Association (PLASTICS). At Protolabs, aluminum molds can be quickly produced by threeaxis milling and hand polished or textured to one of eight surface finishes Two examples of these finishes include PMF0, left, which is a noncosmetic finish used when a polish is unnecessary and an asmilled appearance is acceptable;.

This kind of surface finish is applied in a back and forth motion, so it leaves behind characteristic linear scratches producing a very obvious pattern It’s possible to have an SPI surface finish for B1 which also measures a flatness of Ra 2~3 But this finish doesn’t look the same as A3, nor would the part made from such a tool. Q SPI also produced a "Cosmetic Specifications of Injection Molded Parts" (AQ103) document with a Surface Identification and Classification scheme which closely parallels the Mold Finish Guide scheme, ie, surfaces A through D and grades 1 through 4 but really speaks more about how a part should be inspected This would seem to be. SPI finish standard plaques with black and clear materails for ABS and PC surface SPI surface finish standard with metal scale E Plastic scale size 1×65×2mm of SPI finish standard scale surface with black/clear color F steel plate size 25×48mm of SPI finish standard surface with 12 pcs plate SPI Finish standard SPI A1 SPI SPI A3 SPI B1.

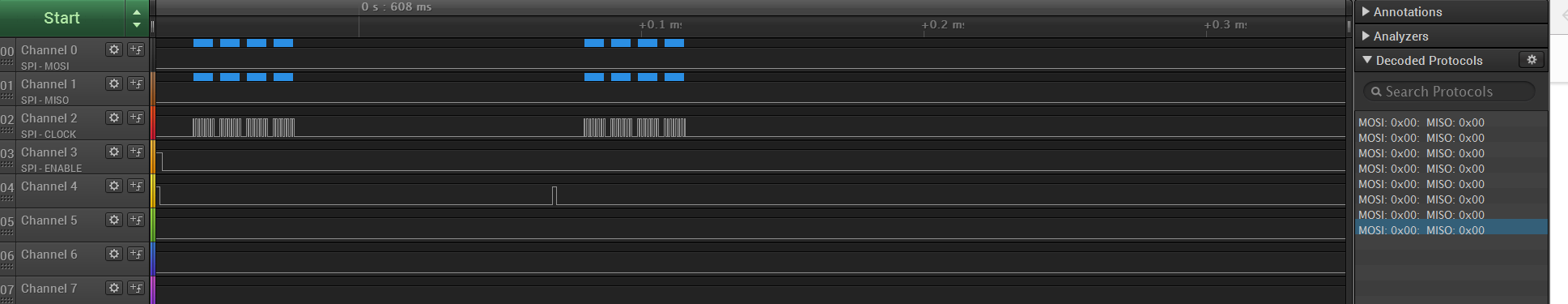

SPI is a synchronous bus with four lines Data master output/slave input (MOSI) and master input/slave output (MISO), clock (SCLK), and slave select (SS or CS) SPI is a full duplex standard, meaning signals can be transmitted in both directions simultaneously, with data rates from a few Mb/s to tens of Mb/s. The SPI standards specify 12 grades of mold finish in four different categories that range from mirrorperfect to dull Shiny Finish—SPI grades A1, , and A3 specify high gloss finished on hardened tool steel molds buffed to a mirror luster with fine diamond powder suspended in oil These finishes are super smooth, shiny, and expensive. The SPI standards specify 12 grades of mold finish in four different categories that range from mirrorperfect to dull Shiny Finish—SPI grades A1, , and A3 specify high gloss finished on hardened tool steel molds buffed to a mirror luster with fine diamond powder suspended in oil These finishes are super smooth, shiny, and expensive.

The mirror plate and mold cavities are polished to an SPI A3 diamond finish The novel ejector system is half in the insert mold and half in the base All mold plates and mirror plates come with soft touch rubber lift handle for comfort and safety A Thandle offers a quick release and lock of molds The base is made of 4130 prehardened steel. Finish Type Materials Used Roughness Averages Results;. Fortunately, SPI continues to make the mold finish standards available While reintroducing the standard on its own, SPI, based on the experience gained, changed the word "standard" to "guide" and expanded it to include 12 finishes (see Figure 1) The original six SPE/SPI mold finishes were encompassed within the new guide.

Exact wattages may vary based on. Injection Moulding Surface Finish Most tool shops have a range of predefined finishes for the tools SPI is a standard, ranging from Polished (SDI A1) to rough (SPI D3) Generally the part will reflect the tool, however for high polish other factors such as resin choice and mould design are also important SPI (Society of. 1 A1 A3 Grade #3 Diamond Buff Grade #6 Diamond Buff Grade #15 Diamond Buff 01 12 23 • Mirror or optimal finishes • Most time consuming and costly finish • Steel grade important to results 2 B1 B2 600 Grit paper 400 Grit paper 3 Grit paper 23 45 910.

I am using a Devilbiss Finishline 4 with a 15mm fluid tip and a #3 HVLP cap If you guys don't mind, it would be great if you could check out the pictures I attached Frankly, I am a bit lost on how to improve the finish / reduce orange peel As directed by the manufacturer, I have set the gun to 23 psi at its inlet, almost full fan. Note that with surface finish measurement, the lower the number is, the smoother — or less rough — the surface is Conversions of Surface Roughness Units Another type of metal surface finish chart might show the conversions between different units for specific surface roughness grades. Injection Moulding Surface Finish Most tool shops have a range of predefined finishes for the tools SPI is a standard, ranging from Polished (SDI A1) to rough (SPI D3) Generally the part will reflect the tool, however for high polish other factors such as resin choice and mould design are also important SPI (Society of.

E Plastic scale size 1×65×2mm of SPI finish standard scale with black/clear color F steel plate size 25×48mm of SPI finish standard with 12 pcs plate SPI Finish surface standard scale of SPIA1/ SPI/ SPIA3/ SPIB1/ SPIB2/ SPI/ SPIC1/ SPIC2/ SPIC3 making by Polish to achieve SPI Finish standard scaleof SPID1/ SPID2/ SPID3 making by Sandblasting to achieve. SPI Finish A1 — Grade #3, 6000 Grit Diamond Buff SPI Finish — Grade #6, 3000 Grit Diamond Buff SPI Finish A3 — Grade #15, 10 Grit Diamond Buff NONGLOSSY SURFACE, PAPER POLISH SPI Finish B1 — 600 Grit Paper SPI Finish B2 — 400 Grit Paper SPI Finish — 3 Grit Paper. Each grade has different requirements for allowable deviation from perfect, with lower numbers allowing for less deviation and higher numbers allowing for more deviation The list below shows all of the finishes specified by SPI A1 (Grade #3 Diamond Buff) (Grade #6 Diamond Buff) A3 (Grade #15 Diamond Buff) B1 (600 Grit Paper) B2 (400.

Exact wattages may vary based on. SPI finish standard plaques with black and clear materails for ABS and PC surface SPI surface finish standard with metal scale E Plastic scale size 1×65×2mm of SPI finish standard scale surface with black/clear color F steel plate size 25×48mm of SPI finish standard surface with 12 pcs plate SPI Finish standard SPI A1 SPI SPI A3 SPI B1. Type of finish SPI Finish Type Grit Range Previous Finish Type Description A1 Grade #3 diamond buff #1 A1 is comparable to #1 Grade #6 diamond buff is slightly finer than #2 A3 Grade #15 diamond buff A3 has more imperfections than #2 B1 600 Grit paper B1 is finer than #3 B2 400 Grit paper B2 is slightly finer than #3.

Purchase SPI MOLD FINISH GUIDE CATALOG #AR106 in Livingston, New Jersey, United States, for US $1000 UNUSED SPI plaques Protective plastic film has not been removed and they are in the same envelopes in which we received them Catalog number AR106. SPI Finish Grade #6, 3000 Grit Diamond Buff SPI Finish A3 Grade #15, 10 Grit Diamond Buff SPI Finish B1 600 Grit Paper. SPI Finish A3 Grade #15, 10 Grit Diamond Buff SPI Finish B1 600 Grit Paper SPI Finish B2 400 Grit Paper SPI Finish 3 Grit Paper SPI Finish C1 600 Grit Paper SPI Finish C2 400 Grit Paper SPI Finish C3 3 Grit Paper SPI Finish D1 600 Stone Prior to Dry Blast Glass Bead #11.

Type of finish SPI Finish Type Grit Range Previous Finish Type Description A1 Grade #3 diamond buff #1 A1 is comparable to #1 Grade #6 diamond buff is slightly finer than #2 A3 Grade #15 diamond buff A3 has more imperfections than #2 B1 600 Grit paper B1 is finer than #3 B2 400 Grit paper B2 is slightly finer than #3. SPI Finish D3 — 3 Stone Prior to Dry Blast #24 Oxide Note that these are finish call outs for the mold itself and not the finished part The final part finish is a factor of the molding material and the mold steel. What is SPI/SPE #3 A discussion started in 03 but continuing through 18 03 Q I received a drawing specifying an SPE/SPI #3 finish on nontextured surfaces and I can't find what this means I looked on the SPI and SPE websites and they have no info available Can you tell me what this polish spec means, and what the #3 means?.

If quality workmanship, quick turnaround, and competitive pricing are important to you then look no further than The Final Finish SPI Finish A1 Grade #3 Diamond Buff Diamond Grade #6 Diamond Buff A3 Grade #15 Diamond Buff B1 600 Grit Paper. SPI Mold finish does not give the same results with all thermoplastic materials Material properties also have an impact on type on injection molding surface finish that can be achieved on a plastic part Below table can give you an idea about recommended spi mold finish for a given plastic material. The SPI mold finish standards have superseded other finishing standards, but customers sometimes use old finish grades when writing mold specifications For example, the Society of Plastics Engineers from the 1960s through 1980s offered a scale of 1 to 6 to specify mold finishes ranging from a highsheen diamond polish to rough blasted surface.

The best way to define the mold finish would be to specify "SPI A1, Optically Clear Mold Finish" Now, this could also be specified as "SPI A3" because it depends upon the material being molded, as with polycarbonate It is best to check with your material suppier for the finish they recommend for their product to be molded. And gloss finishes are SPIA1, SPI, and SPIA3, or “diamond buff” finish Rougher surface finishes from media blasting are SPID1, SPID2, and SPID3 for “dry media blast” surface. (Close to A3 diamond with a directional pattern) B2 400 Grit Paper Close to a B1 paper finish, but with a deeper directional pattern Less shine than a 600paper finish 3 Grit Paper Almost like a B2 paper finish, but with a slightly deeper directional pattern B4 240 Grit Paper Deeper directional pattern than 3 paper finish.

SPI specifications include matte finishes SPIB1, SPIB2, and SPI are referred to as “paper” finish;. SPIC1, SPIC2, and SPIC3 as “stone” finish;. An SPI A3 is a fine choice for release where a high gloss appearance is not required All diamond finishes work well with chrome and nickel Paper Finishes, SPI B1 to – Next to diamond polishing, paper finishes are the second most refined finishes available.

Tool Finishing (SPI) The US Society of the Plastics Industry (SPI), now with its name changed to Plastics Industry Association, coded in the past a series of steel tool finishes, noting as well how those could be achieved A3 (Grade #15 Diamond Buff) B1 (600 Grit Paper) B2 (400 Grit Paper) (3 Grit Paper) C1 (600 Stone) C2 (400. SPI* standard Finishing Method Typical surface roughness Ra (μm) Super High Glossy finish A1 Grade #3, 6000 Grit Diamond Buff 0012 to 0025 High Glossy finish Grade #6, 3000 Grit Diamond Buff 0025 to 005 Normal Glossy finish A3 Grade #15, 10 Grit Diamond Buff 005 to 010 Fine Semiglossy finish B1 600 #Sand Paper 005 to 010 Medium Semiglossy finish B2. SPIC1, SPIC2, and SPIC3 as “stone” finish;.

400 #8 Mirror Finish 4 8 500 #8 Supermirror Finish < 4 3 8 500 #8 Supermirror Finish 4 01 16 04 4 10 N3 Buff #400 2 006 8 02 N2 1 0025 4 01 N1 C SURFACE FINISH CROSS REFERENCE CHART Common USA name ASTM 80. SPI A3 – 10 grit, grade #15, diamond buff SPI Bn, Paper Finishes SPI B1 – 600 grit paper Still a glossy finish, but less reflective than the diamond polishes SPI B2 – 400 grit paper;. These finishes are often more difficult to produce but can be much more visually attractive than a simple SPI A3 polish If you have a slightly textured plastic piece nearby, it might have been finished with MT, one of the most common textures used in molded parts.

SPI Finish D3 — 3 Stone Prior to Dry Blast #24 Oxide Note that these are finish call outs for the mold itself and not the finished part The final part finish is a factor of the molding material and the mold steel. To ensure color consistency, SPI uses precise bin selection and strict quality processes to maintain a 3step (MacAdam) SDCM on all white LED lampings Published LED luminaire wattages are calculated using a typical power supply efficiency of %;. SPI A1 – 6000 grit, grade #3, diamond buff This is your common shiny mirror finish SPI – 3000 grit, grade #6, diamond buff;.

400 #8 Mirror Finish 4 8 500 #8 Supermirror Finish < 4 3 8 500 #8 Supermirror Finish 4 01 16 04 4 10 N3 Buff #400 2 006 8 02 N2 1 0025 4 01 N1 C SURFACE FINISH CROSS REFERENCE CHART Common USA name ASTM 80. © 18 Swiss Precision Instruments, Inc. And gloss finishes are SPIA1, SPI, and SPIA3, or “diamond buff” finish Rougher surface finishes from media blasting are SPID1, SPID2, and SPID3 for “dry media blast” surface.

SPI Surface finhish Standards,spi mold finish standards, spi mold finish chart, spi mold finish guide, spi surface finish chart, spi surface finish specifications. Type of finish SPI Finish Type Grit Range Previous Finish Type Description A1 Grade #3 diamond buff #1 A1 is comparable to #1 Grade #6 diamond buff is slightly finer than #2 A3 Grade #15 diamond buff A3 has more imperfections than #2 B1 600 Grit paper B1 is finer than #3 B2 400 Grit paper B2 is slightly finer than #3. In the US, most of us are very familiar with the Society of the Plastics Industry’s standard surface finish definitions, such as an A1 diamond buff, C1 Grit Stone or a B2 Grit Paper finish As you can see, the RA equivalent value of that A1 diamond buff is a 0 – 1µ, while the C1 Stone finish has a 10 – 12µ RA value and the B2.

Injection Molding SPI A1 SPI SPI A3 SPI B1 600 Grit Paper Typical Application Medium polish parts SPI B2 400 Grit Paper Typical Application Medium polish parts SPI 3 Grit Paper Typical Application MediumLow polish parts SPI C1 600 Stone Typical Application Low polish parts SPI C2. SPI surface finish chart for roughness technology SPI a1 is comparable to RA01 made by #3 diamond buff SPI a2 is slightly finer than a1 and RA12 made by #6 diamond buff SPI a3 has more imperfections than a2 and R3 made by #15 diamond buff SPI b1 is finer than a3 and R3 made by 600 grit SPI b2 is slightly finer than b1 and R5 made by 400 grit SPI b3 is comparable to R10 made by 3 grit. SPI specifications include matte finishes SPIB1, SPIB2, and SPI are referred to as “paper” finish;.

Mold Texture Spi Mold Finish Plastopia

Spi 2 To 500 Ra Micro Inch Surface Finish Nickel Surface Finish Comparator Msc Industrial Supply

Vdi 3400 Surface Finish Edm Surface Finish Vdi Surface Upmold

Spi A 3 Finish のギャラリー

Polished Finishes The Tool Hub

Item Detail Ar 106 Mold Finish Guide

Fundamentals Of Plastic Part Design Part 6 Ejection And Surface Finish Rex Plastics

Plastic Adhesive Bonding The Sabreen Group Inc

Surface Textures For Plastic Injection Molding Tools

Spi Surface Finish Standard Of Metal Plastics Scale

Esp66 Spi Write Doesn T Finish Before Cs Goes High Issue 3487 Micropython Micropython Github

How To Choose Injection Molding Surface Finishes And What Are The Grades 3d Insider

Vdi 3400 Vs Spi Finish Surface Roughness Conversion Upmold

Q Tbn And9gctndz Cqlco3e4bjnlkr6jxttnlp581nxcpcyw4ijrsvidii6vi Usqp Cau

Smashrun Blog How To Use Spi

Mold Texture Spi Mold Finish Plastopia

14 443 6 Spi Micro Surface Finish Comp Plate 0 4 50 Higher Precision

Kenny Page 3 Pim Plastic Molding Company

Spi Mold Finish Standards Industry Knowledge Abis Mold Technology Co Ltd

Mold Polishing Blasting Finishes Spi Finish Chart Bales Usa

Vdi 3400 Mold Texturing Vdi Finish Edm Surface

Spi Mold Finish Standards Industry Knowledge Abis Mold Technology Co Ltd

Learn More About Our Finishes Xometry

Spi Mold Finish Practical Approach Pro A Innovation Limited

Injection Molding Spi Surface Finishes 3d Hubs

Spi Surface Finish Standards Spi Mold Finish Guide Upmold

Spi Surface Finish Standards Spi Mold Finish Guide Upmold

How To Communicate Color Material And Finish Effectively Fictiv

.jpg)

Spi Standards

Art Vs Science The World Of Metal Polishing

Understanding The Ate Spi Serial Peripheral Interface

Best Practices For Bonding Semi Crystalline Thermoplastics Plastics Decorating

Surface Textures For Plastic Injection Molding Tools

Learn Efficient Light Pipe Design Using Virtual Prototyping Presented By Lambda Research Corporation 25 Porter Rd Littleton Ma Pdf Free Download

Spi Spe Finish Comparison From Dzynsource Llc Dzynsource Mold Engineering Software

Cleaning Molds Part I Plastics Technology

Spi 0 8 To 100 Ra Micro M Surface Finish Nickel Surface Finish Comparator Msc Industrial Supply

Spi Surface Finish Standard Of Metal Plastics Scale

Dual Water Temperature Probe Over Spi Or Another Method Esp66

Technical Polishing Surfacetec

Mold Texture Spi Mold Finish Plastopia

Spi Mold Finish Guide And Guidelines Injection Molding Texas

Gar To 900 Micro Inch Surface Finish Nickel Surface Finish Comparator Msc Industrial Supply

Spi Mold Finish Guide Spi Mold Finish Standards Surface Roughness

Plastic Injection Molding

Www Balesusa Com Media 1273 Bales Mold Finish Guide Spi Order Pdf

Vdi 3400 Vs Spi Finish Surface Roughness Conversion Upmold

Is A Member Of Indiamart Following Details Of The Company Have Been Verified Indiamart All India All India Search By Voice Get Best Price Covid 19 Supplies Mask Sanitizer Other Hygiene Supplieshand Sanitizer Disinfectantface Maskn95 Maskppe

Technical Polishing Surfacetec

Spi Surface Finish Standards Spi Mold Finish Guide Upmold

Finishing An Injection Molded Part

An Overview Of Injection Molding Surface Finishes

How To Enable Spi Master Driver In Raspbian Using Raspi Config Techcoil Blog

Inkjet Printing And Adhesion Of Low Surface Energy Polymers Plastics Decorating

Fowler 2 To 492 126 Micro Inch Surface Finish Nickel Surface Finish Comparator Msc Industrial Supply

Surface Finish Understanding Mold Surface Lingo Moldmaking Technology

Www Dme Net Wp Content Uploads Technicalguides Micro Finish Mold Tool Finish Guide Pdf

Spi Surface Finish Standards Spi Mold Finish Guide Upmold

How To Enable Spi Communication With Raspberry Pi Gpios Online Shouter

Front Lg Berkeley Sourcing Group

Mold Texture Spi Mold Finish Plastopia

Finishing An Injection Molded Part

Mold Polishing Alliance Specialties And Laser Sales

Spi Finish Spi Surface Yuan Su Mold Texturing Ltd

Switchable Beam Delivery Spi Lasers Uk Ltd Summer Europhotonics

Spi Reg Surface Roughness Standards Sets Web 30 695 1

Spi Micro Surface Finish Comparator Plates Reaming Drilling 14 445 1 Penn Tool Co Inc

Cdn2 Hubspot Net Hubfs Design Guides Xometry Designguide Injectionmolding Pdf

Spi Finish Spi Surface Yuan Su Mold Texturing Ltd

Mold Texture Spi Mold Finish Plastopia

Surface Textures For Plastic Injection Molding Tools

S U R F A C E T E C H Premium Mold Polishing And Cavity Restoration

Fundamentals Of Surface Finish In Injected Molded Parts Midstate Mold

Surface Finish Samples Injection Molding Free Xcentric Mold

Spi Mold Finishing Guide Easy Conversion Reference For Spi Ra

Mold Polishing Blasting Finishes Spi Finish Chart Bales Usa

Jameslin Jameslin1158 Profile Pinterest

Spi Standards Consistent Results On Finished Productts Acorn Gencon Plastics

Mold Texture Spi Mold Finish Plastopia

Q Tbn And9gcqfnz490ox Oa2iyme6 4o 9plrnzp6unu85ej Tdb6cejfmpxt Usqp Cau

Spi Surface Finish Standards Spi Mold Finish Guide Upmold

Spi Finish Card It Is Finished Cards Texture

Spi Mold Finish Practical Approach Pro A Innovation Limited

Spi 0 4 To 50 Ra Micro M Surface Finish Nickel Surface Finish Comparator Msc Industrial Supply

Polishing Finishing Services Erie Pennsylvania

Q Tbn And9gcqfnz490ox Oa2iyme6 4o 9plrnzp6unu85ej Tdb6cejfmpxt Usqp Cau

Q Tbn And9gcsfqkohp7q6dz5uvj5ruxmzdgokdhnkuk3wimb9boytf5pxecnr Usqp Cau

An Overview Of Injection Molding Surface Finishes

An Overview Of Injection Molding Surface Finishes

Surface Finish Of Plastic Injection Molding Product Ecomolding Com

Finishing Services Shineyuu

Spi Mould Finishes Geomiq

Spi S Mold Surface Call Out Equivalent For Diamond Polished Optical Clear Cr4 Discussion Thread

Comparing Ptfe And Pfa Fluoropolymers As Wetted Parts In Advanced Semiconductor Manufacturing News

Plastic Surface Finish Chart

Spi Micro Surface Finish Comparator Plates Precision Tools Light Tool Supply Precision Measuring Surface Surface Finish

Mold Polishing Blasting Finishes Spi Finish Chart Bales Usa

Ppt Spi 0807 9 6 States Of Matter Spi 0807 5 5 Fossils Powerpoint Presentation Id

White Paper Enhancing Cosmetic Appearance On Molded Parts

Spi Mold Finish Surface Finish For Injection Molded Parts

Adding Spi To Simple Peripheral On Cc2650 Send Data But Never Finish Transfer Bluetooth Forum Bluetooth Ti E2e Support Forums

Spi Finish Card It Is Finished Cards Texture

Surface Textures For Plastic Injection Molding Tools

Spi Finish Card Clear Version Youtube

Learn More About Our Finishes Xometry